Iron or Ayas (अयस्)

Iron, called as Ayas (Samskrit: अयस्) heralded a new era in the history of mankind. Iron technology has a special place among the ancient technologies that accelerated the pace of progress and brought prosperity in society. In human history Iron Age succeeded Copper-Bronze Age as iron required a different kind of skill and a higher level of metallurgical expertise. The craftsmen who were adept in working with copper and its alloys and other glittering metals like gold, silver etc., that could be used in their native form at a much lower temperature could not smelt iron with the same technique. India has rich iron ore deposit. The ore is not only widely distributed but also easily accessible in the form of nodules scattered on the earth's surface. This must have facilitated easy hand picking of rich ore nodules by the early or primitive metal workers. However, wide distribution and easy access to the ore were insufficient to produce metallic iron and required skilled metal workers possessing sufficient metallurgical know-how. Archeological researches and archival accounts including foreign records by travelers or historians of ancient India bear that Indian iron and steel had gained significant recognition in the ancient world.[1] India abounded with vast deposits of many minerals and precious stones, thus mineralogy was an important topic dealt with even in texts such as Rigveda that helped develop and sustain many metal and alloy industries.

Introduction

The precise manner in which man discovered iron is unknown and may have been accidental. Man must have come to know of iron through meteorites; they contain high percentage of nickel and is difficult to forge. The earliest recorded instances of the use of meteoric iron are from Egypt and Mesopotamia. It is more likely that iron was first found in ashes of a fire set up by chance near the outcrop of an iron rich mineral. A folklore of the `Bastar tribe of central India states that their forefathers first made iron accidentally in a hollow anthill. Meteoric iron did not offer scope for any techniques involved in iron working such as smelting and forging and thus may have hardly played any role in the development of Iron age. The intentional heating of iron mineral with charcoal and development of smelting process heralded the beginning of iron making and subsequently its fabrication into implements and weapons marks the emergence of iron age.[2]

Greek historian, Herodotus, stated in his book that Indian soldiers fought with iron-tipped arrowheads in their battles. There are records stating that swords of Indian steel were gifted as a tribute to monarchs emphasizing their valuable nature and they were exported to different parts of the ancient world.[1] In India, D.K. Chakrabarti states that Iron has entered as a productive system by 800 B.C. Many areas from Central and Southern India, show evidence of Iron ore and Iron smelting indicating the earliest use of Indian iron in India. The iron and steel produced in early days was also shaped into useful articles. The primacy of iron technology in the Indian subcontinent is well established and there are several published books[3][4][5] and articles on the state of ancient Indian iron technology. Sushruta, the medical science expert in ancient India described many surgical instruments in his book Sushruta Samhita (third or fourth century BCE).[6] The present article includes the chronology of time as stated in particular authors mentioned in the references in some instances and are not the views of the author of this writeup.

Does Ayas mean a metal or iron?

The history of iron can be traced back based on the historical and archaeological sources including modern radiocarbon dating. The early hymns of Rigveda revealed the knowledge of extracting metals from ores. 'AYAS' (iron) was the third Rig-Vedic shining metal (after gold and silver). Ayas meant different meanings in different periods. In early Vedic period, it means either copper or copper alloys.[7] According to some scholars[2][7] Ayas meant 'iron', while others, Lallanji Gopal, Tripathi[1] argued that it stood for 'metal' in general in Rigveda. Yajurveda mentions gold, silver, copper, lead, tin and iron in the famous Rudra adhyaya. The terms 'krishna or shyamaayas' (the black metal) and lohitaayas (the red metal) denoting iron and copper, respectively were coined in the Shukla Yaurveda (28.13) text.[1] These words were also found in Atharvaveda (9.3.7) and other synonymous forms are krishnaayas (Chand. Upan. 4.1.6, Taitr. Brah. 3.2.6.5) and other references in Chandogya Upanishad and Jaimini Upanishad.[8]

अश्मा च मे मृत्तिका च मे गिरयश् च मे पर्वताश् च मे सिकताश् च मे वनस्पतयश् च मे हिरण्यं च मे ऽयश् च मे श्यामं च मे लोहं च मे सीसं च मे त्रपु च मे यज्ञेन कल्पन्ताम् ॥ (Yaju. Samh. )[9] aśmā ca me mṛttikā ca me girayaś ca me parvatāś ca me sikatāś ca me vanaspatayaś ca me hiraṇyaṃ ca me ’yaś ca me śyāmaṃ ca me lohaṃ ca me sīsaṃ ca me trapu ca me yajñena kalpantām ||

However, according to A. K. Vaish, et. al.[2] Rig-Vedic hymns have reference to the soldiers putting on coats of mail (a jacket covered with or composed of metal rings or plates, serving as armour) and using metallic helmets. Ancient Indians deployed the use of iron in agriculture and warfare. The uses of iron extended down to southern tip of Tamil Nadu. Based on the weapons and implements cited in Rigveda and the Puranas, iron making technology existed to fulfill man's needs for war and peace.[2]

Rigveda begins with a prayer to Agni to bless mankind with all worldly pleasures. One of the major contributions of the discovery of fire and pyrotechnology was its use for the extraction of metals from their minerals. Prakash[10] postulated and described the havankund (yajnakunda) as the open air laboratory of the Vedic times which may have been responsible for the discovery and development of the many new uses of the thermochemical energy.[1]

Historical evidence of Iron in Ancient India

Rapid developments in iron making and its use took place around 1400 B.C. The history of early iron smelting, practiced by the tribal artisans in different regions of ancient India dates back to 1300 to 1200 B.C. The use of iron was relatively unknown except in areas where iron bearing minerals were abundant. Prakash and Tripathi[11] have documented the early iron age cultures, which could have been independent of each other, arising in five different zones of India. These five cultures were

(i) Cairn Burial culture in northwestern India

(ii) Painted Grey Ware (PGW) culture in north India

(iii) Black and Red Ware (B&RW) culture in northeast India

(iv) Megalithic culture of central India and

(v) Megalithic culture of Peninsular India.

The chalcolithic traditions, also known as the Copper Age, refers to the time period in history when people began using copper and other metals, in (a) the premature and post Harappan (b) Peninsular India and (c) Eastern India gradually gave rise to the iron age cultures in the respective areas. West Bengal and Bihar in India are endowed with high grade copper as well as iron ores and definitely constituted one of the nuclear zones for the ancient metallurgical traditions of India. South India evolved mega (big) lithic (stone) culture in which the burials were surrounded by a circle of stone boulders. This culture extending gradually to the central India and even trans—Vindhyan areas, exhibited early traditions of the use of iron. The earliest phase of the Iron Age in the south has been revealed in the excavation at sites in Karnataka. Thus the traditions of Iron age evolved over centuries across a large section of the subcontinent, starting in southern most India. The dates of the earliest iron age sites in India show that the discovery and use of iron started around 1200 B.C. indigenously and independently in at least three nuclear zones—Karnataka area in the south, U.P.—Rajasthan area in the north and West Bengal—Bihar area in the northeast.[2]

Archeological Excavations

The following are a few iron artifacts excavated and investigated in Indian archeological sites.[2]

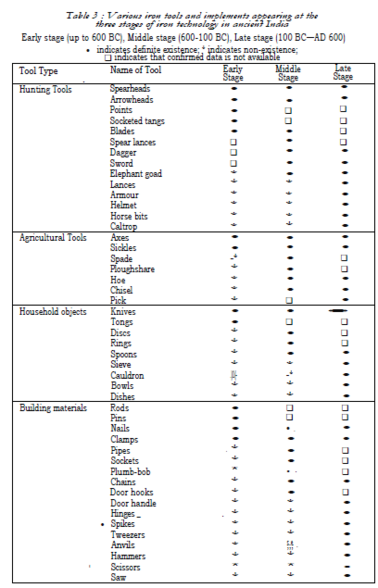

- A large number of iron implements have been unearthed at Adittanallur, Tamilnadu at a burial site which is dated to around 250 B.C. A table of various iron tools and implements appearing at the three stages of iron technology in ancient India has been provided below.

- Iron implements comprising of agricultural implements, blacksmith tools etc., have been unearthed at Taxila. Besides numerous ingots of iron, iron spearheads, spikes and nails belonging to the second century A.D. have been found in UP, near Basti and Kapilvastu.

- The great battle of `Kurukshetra' was fought which witnessed the extensive use of iron weapons and armour.

- Sushruta, the great surgeon of ancient India indicated that even in the early period, Hindus had learnt the art of manipulating the lancet and handled the simple surgical instruments made of iron and steel.

- At Pandu Rajar Dhibi in West Bengal use of iron has been traced to first millennium B.C.

- Matured iron age had existed around 8th century B.C. in Pandu Rajar Dhibi in West Bengal. The hardening and quenching methods were observed in a third century B.C. sickle, which is so far one of the earliest Indian specimens exhibiting the steeling process. The length of the sickle was 255 mm and the maximum width 22 mm. The internal curved region of the agricultural tool had a sharp cutting edge. The chemical analysis revealed that it was low carbon steel-carbon 0.22%, copper 0.15%, nickel 0.13%, cobalt 0.11%, rest iron.

- A second century B.C. sample of iron razor from Ror, district Kangra, Himachal Pradesh, showed, apart from massive ferrite, martensite plates indicated the technique of rapid quenching.

- The excavations at Bodh Gaya monastery built by Ashoka in third century B.C., have brought to light the iron clamps.

- Alexander defeated Porus of Taxila in 326 B.C. and received from him a gift of 100 talents of steel.

- Excavations at the Garh Kalika mound on the outskirts of Ujjain revealed that iron was known to its ancient dwellers from the earliest period.

- Iron articles such as spikes, nails and pieces have been unearthed in the monastery at Piprahwa, about 20 km from the ruins at Kapilvastu (near Nepal border).

- The famous pillar at Mehrauli, near Kutub Minar in Delhi (more than 7 meters in height and about 7 tonnes in weight) was originally erected at Mathura and later on re-erected at Delhi. It shows that Megalithic iron smiths had evolved the technique of forging small blooms into huge iron piece.

- The Dhar pillar is dated to 12th century A.D. It was intact till 1304 A.D. and then broken into three pieces. Its height was more than the double the Delhi pillar.

- The pillar at Mount Abu stands at the temple of Achaleswar, which was built in 1412 A.D. It has a trident on its top.

- The famous sun temple at Konark in Orissa has wrought iron beams. They are dated to 13th century A.D. Several iron beams have been used in the ancient temple of Konark in Orissa which was built in the 9th century.

- In the Jagannath temple of Puri in Orissa, built in the 12th century A.D. 239 iron beams have been used.

- The iron trident in Tanginath temple belongs to 12th century A.D.

- Babar used guns in first battle of Panipath in 1526 A.D. Guns were introduced in southern India by the Portuguese. Most Mughal guns were generally constructed of iron bars of square section.

During the 17th and 18th centuries the iron industry got a fillip and artisans producing iron and black-smiths making weapons were kept busy. Ironmaking was practiced widely in many parts of the country by artisans called lohars, basing on naturally available iron ore and charcoal for reduction. This industry was active in various places in U.P., Bihar, Bengal, Orissa, Maharashtra, Madhya Pradesh, Mysore, Assam and Madras. The furnaces were small up to 3' in height and made of mud, with bellows being used to blow the air. The industrial revolution in the 18th century led to the West gaining superiority in materials development and utilization over the rest of the world.[2]

In the 19th century, attempts were made in India for the manufacture of iron by modern methods. Kulti works consisted of two blast furnaces, each capable of producing 20 tones of grey pig iron for casting and foundry. Tata Iron and Steel Company which was founded in 1904 at Jamshedpur, performed its preliminary work during the closing decade of 19 century itself. With the establishment of Tata Iron & Steel Company Limited (TISCO), there was gradual extinction of old indigenous smelting industry carried on by persons known as Asura, Lohars and Agarias etc. The extinction was also due to limited supply of charcoal as a result of forest conservation. Later on many smelters started purchasing ready made iron and started working as a blacksmith in the villages. Metallurgical skills gained in India receded to the background being restricted to making of utensils, idols, ornaments, industries specializing in exquisite crafts of idol making, jewelry etc., in selected areas including tribal areas all over the country. The ancient industry is still in existence in several parts of India such as Bastar in Chhattisgarh State, Salem in Tamil Nadu, Jiragora (Koraput) in Orissa, Kamajoda (Joda) and Bishunpur in Bihar and also Nalanda, Valley, Mandla, Nagpur, Rajdoha and some remote region of Northern Eastern India.[2]

The iron produced in the indigenous furnaces was wrought iron. It contained low percent-age of carbon due the lower absorption of carbon in ancient iron making furnaces. Steel was produced by carburization of wrought iron during this period. It is said that India is the first producer of carbon steel (wootz). In fact, India was considered to be the center of origin of iron and steel industry in the world. It is possible that iron age in India had started about 3000 years before the industry started in European countries. The Damascus swords which became famous in Europe were made from Indian wootz. In those days, Hyderabad and Madras in South India were the centres of production of wootz. The process of wootz making was specially popular in the districts of Salem and Tiruchirappalli in Madras, besides the Hyderabad area, in Andhra Pradesh and Mysore. The ancient Indian steel was highly priced in world market. The possibility of a country wide manufacture of iron existing from quite early times, is also indicated by the references to the working of iron mines in Bajuha, Subha Bengal, Keroh, Subha Kashmir, Kumaon, Khasi Hills, Subha Delhi, besides at Nirmal and Indore in Ain-i-Akbari.[2]

Pyrometallurgy

The extraction of iron is pyrometallurgy. It is the extractive metallurgy which consists of the thermal treatment given to minerals or ores to recover the metal. The process involves chemical reactions at elevated temperature. The process of extraction of iron is fundamentally very simple as it consists essentially of the reduction of iron oxide by carbon. But as molten iron dissolves carbon and other impurities, iron obtained is impure and is known as pig iron or cast iron. The ore (red haematite or hydrated oxide or carbonate) is calcined in shallow kilns to remove moisture, carbon dioxide etc. The ore thereby becomes porous and is then more easily reduced in the blast furnace.[12]

Iron Ores

- Oxides: Red Hematite - Fe2O3 (Oxide ore), and Brown Hematite (Limonite) - 2 Fe2O3 . H2O and Magnetite (Fe3O4)

- Carbonates: Spathic Iron ore or Siderite - FeCO3 (Carbonate ore) is rarely used.

- Sulphides: Iron pyrites – FeS2 and Chalcopyrites – CuFeS2

Iron is normally extracted from its oxide ore called haematite and magnetite and is rarely extracted from carbonate ore called siderite. Iron pyrite is an important source of sulphur and therefore it is not used in the extraction of iron.[12]

Chemical Reaction

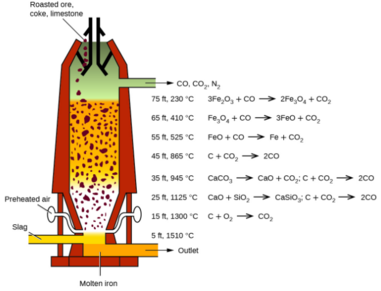

The overall reaction for the production of iron in a blast furnace is as follows:

Fe2O3(s)+3C(s)−Δ→2Fe(l)+3CO(g)

Where Fe2O3(s) stands for Hematite ore (Ferrous Oxide, s = solid), C stands for Carbon (in the form of solid coke), Δ represents the energy requirement for the reaction to take place, Fe stands for Ferrum (elemental Iron, l = liquid) and CO stands for Carbon monoxide (g = gaseous state)

Iron compounds in the ores could be reduced by carbon; and for a long time, charcoal was the form of carbon used in the reduction process. Charcoal was replaced by Coke, a form of carbon formed by heating coal in the absence of air to remove impurities, improving the reduction process. As seen in the equation above, the actual reductant is CO, which reduces Fe2O3 to give Fe(l) and CO2(g).

Steps in the Extraction of Iron

The extraction of iron involves following steps.[12]

- Collection of raw materials

- Washing and concentration or dressing of the ore

- Preliminary roasting and calcinations

- Reduction or smelting in a Blast Furnace

Collection of raw materials: Iron is the most abundant metal in the earth's crust. Because of its strong affinity to oxygen, it is not found in the elemental state but predominantly in its combined forms such as oxides, and much less as sulphide and carbonate. Iron is predominantly extracted from its oxide ore, hematite.

Ore Dressing: After washing with water, ore is subjected to magnetic separation. This way the ore is rich in oxide of iron. Washing removes the silicious impurities, concentrating the ore.

Preliminary roasting and calcinations: The concentrated ore is roasted and calcined with little coal and excess air in a shallow furnace. Following changes take place during roasting and calcinations.

(i) Moisture escapes as steam and organic matter present burns off to give CO2 Sulphur and arsenic are oxidized to form their volatile oxides SO2 and As2O3 respectively.

(ii) Ferrous oxide is converted to ferric oxide which avoids formation of ferrous silicate in the slag during smelting. The reactions that happen in the furnace at various temperatures are elaborated in the image.

(iii) The mass becomes porous and thus makes it more suitable for reduction to metallic iron.

Reduction or smelting in a blast furnace: The roasted and calcined ore ( 8 parts ) is mixed with coke ( 4 parts ) which acts as a reducing agent and limestone ( 1 part ) which acts as a flux. The mixture is introduced in a tall Blast Furnace. The blast furnace has two functions (i) to reduce the ore to metallic iron and (ii) to remove the impurities in the form of slag.

Products of the Blast furnace

The products obtained from the blast furnace include Pig Iron, Slag and Flue gasses.[12] Pig iron is the most impure form of iron having impurities. Slag is mostly calcium silicate and some amount of aluminum silicate. Gasses produced in the extraction process are called flue gasses containing CO (carbon monoxide), Nitrogen and hyderogen.

Commercial forms of Iron

- Pig iron - The most impure form of iron, it contains about 1.5% to 4.5% Carbon. Other impurities like Si, P, Mn and S are present up to about 1.5 %.

- Cast Iron - Pig iron when is remelted in a vertical furnace can be poured into moulds. It is then called cast iron. When the pig iron is suddenly cooled, crystalline cast iron is obtained called as white cast iron. In this form carbon is present combined with iron as iron carbide. However, if the molten pig iron is cooled gradually in sand moulds, a graphite coloured iron is formed called grey cast iron. Major part of cast iron is used to manufacture steel and other heavy machinery.

- Wrought or Malleable iron – It is the purest form of iron. It contains about 0.2 % carbon.

- Steel – It is an alloy of iron with carbon and other elements like manganese, silicon and phosphorus. It is midway between cast and wrought iron as far as impurities are concerned. It contains 0.1 to 1.5 % carbon.

Types of Ferrous Materials

The Rasaratnasamucchaya describes three types of ferrous materials.

| Kinds of Iron

(Loha) |

Sub-categories | Properties |

|---|---|---|

| Kanta Loha (Soft Iron) | Bhramaka | Very soft magnetic iron |

| Chumbaka | Mildly magnetic, sticks to iron pieces | |

| Karsaka | It can attract iron objects | |

| Dravaka | Very strong magnetic iron | |

| Romaka | Permanent magnet, develops strong magnetic field around it. Itmay be Ekmukh or sarva mukh | |

| Tikshna Loha (Carbon steel) | Khara | Develops good cutting edge, breaks on bending |

| Sara | Softer iron and it has fibrous fracture | |

| Hrnnala | Hard and tough having fibrous fracture | |

| Travaratta | Develops good cutting edge | |

| Vajra | Has good hardening and tempering property, has bluish color and hard cutting edge | |

| Kala | Develops hard cutting edge after blue tempering | |

| Munda Loha (Cast Iron) | Mrdu | Soft brittle iron may be grey cast iron, has low melting point |

| Kunda | Mottled grey iron | |

| Kadara | White cast iron |

Extraction Process in Ancient Times

Iron ores were widely distributed in Indian subcontinent. However they were delayed to smelt Iron. The reason is that the primitive condition of furnace has produced temperature about 1100°C which is required for Copper smelting. But Iron needs a high temperature almost above 1500°C for the ore to smelt into a liquid. Little solid grains of Iron have obtained by low temperature as 800°C. Iron is a soft and spongy material which had to be admixed with carbon in proper proportion to obtain sufficient sharpness and hardness. It was obtained from ores at high temperature. Iron has more impurities than Copper. This impurity is removed by using a catalytic flux such as lime to produce the slag. Iron produced by smelting is of 3 kinds based on its carbon content:

- wrought iron (Kanta Loha)

- cast iron (Munda Loha)

- carbon steel (Tikshna Loha)

Quenching and tempering was also learnt along with steeling of Iron. Quenching consists immersing the red hot metal into water. Metal would become hardened by this process. Tempering consists of repeated heating of the metal and allowing it to cool slowly while it is hammered.[14] Raw iron, wood and carbon are heated in earthen bowls at a temperature of 1535°C and then, slowly cooled over 24 hours. This gives high quality carbon rich steel. A sword made of this steel is so sharp and strong that it even cuts silk smoothly.

The ancient process of iron making has been vividly described in the folk songs of `Chokh Agaria' from Lapha. One of these songs as translated by Joshi is as follows:[5]

She presses down the bellows with the strength of her heels, He wields the heavy hammer with all his might

From the ground he gets stones..The fire burns fiercely as the bellows blow.

The little hammer clatters, tinning tanang, A shower of sparks flies into her breast

He puts it in black He pulls it out red, Standing he beats it

The chokh girl blows the bellows at the forge, Like a drum it sounds Datur Thunda'

How happy I feel, The chokh boy beats with the hammer

The hammer whistles as he swings it round, And I feel very happy.

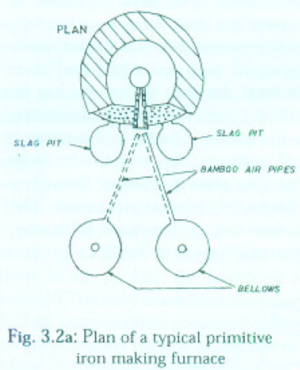

As it appears from the above mentioned song the whole operation was a family affair controlled by the headman and his wife and the technology was maintained as a secret, passed on from generation to generation. The younger generation participated in the activities and when by the age of 17 to 20 they were trained in all the skills of the trade, they were permitted to marry and operate their own furnace. The actual practice of iron making can be divided into the following six steps-[5][13][15]

- Collection of raw material i.e. iron ore, wood and refractory clay: In spite of the abundantly available hematite deposits, ancient smelters preferred to use low grade magnetite ore. The ore was concentrated by panning in the water stream. Ore is calcined to remove moisture and associated organic matter and broken to small pieces. The charcoal used for heating the ore and generating the reducing gas (CO) was produced from a variety of woods depending upon their availability in the region, and generally no basic flux was used to adjust the properties of the FeO rich fayalite (2FeO.SiO2) slag formed during smelting. Refractory clay and stiff mud are used for making the furnace.

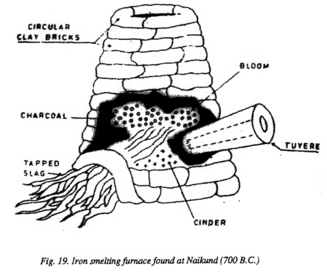

- Construction of the furnace and the tuyere pipe: Ancient furnaces were constructed using curved bricks made of refractory clay. They used two distinct types of furnaces in their operation, which differ in their physical form. The basic principle of operation is same for both. Although the furnaces look crude they were made with great precision, their dimensions being fixed on the basis of experience of the head smelter. The furnaces were constructed using the breadth of man's fingers Angula (about 80mm) as a unit of measurement. The other scales were Bitta i.e., the distance between the tips of the little finger and the thumb in the expanded form (about 240mm) and `Hasta' i.e., the length of the fore arm (about 475 to 500mm). Furnaces were of two kinds: [15]

- Fosse type where the furnace is of shaft type and completely subterranean i.e, constructed below the ground level by digging a small cylindrical pit or shaft as shown in the figure. Bowl type furnaces were also constructed.

- Aerial type furnace is where the furnace is partly subterranean and constructed over a rectangular pit.

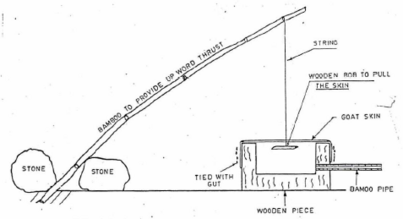

- Making and fixing the bellows: Bellows were made of buffalo hide. The blow pipes used were of bamboo. Furnace hearth was prepared by lining it with 'Kodon' paddy chaff or charcoal powder mixed with clay. One clay pipe is inserted through a parabolic opening in the bottom of the furnace which acts as a tuyere. The opening through which the tuyere is introduced is then luted with clay.

- Drying, firing and operating the furnace: After the dried furnace and the raw material were ready the furnace was charged with dried wood chips and then filled with charcoal up to the top. A ritual pooja and havan were performed praying for the successful operation of the furnace and then it was ignited using a little of the sacred fire from the havan. This was introduced inside the furnace through the tuyere pipe. When the wood starts burning, the bellows were operated slowly to build the fire inside the furnace. After the yellow flame appeared at the mouth of the furnace the blowing rate was increased to raise the furnace temperature. As the charcoal got consumed, ore was charged and the blowing was continued till a translucent blue flame appeared at the top. Blue flame indicated that the furnace reached a temperature of > 1000oC and the charcoal is burning to generate CO gas. At this stage the furnace was charged with alternate layer of ore and charcoal in the ratio 1:2 and the air blowing rate was adjusted and controlled to maintain steady condition. The temperature inside the furnace was visually examined by peeping through the tuyere pipe and after about one hour the first slag was tapped. The fluidity .of the slag, its quantity as well as colour on solidification were indicators of successful operation of the furnace. The slag was either tapped periodically or continuously throughout the furnace operation. When sufficient charges of ore had been made, it was followed by few blank charges of charcoal only, and the air blowing rate was increased to consolidate the reduced iron into a large porous lump and separate it from the FeO rich fayalite (2FeO.SiO2) slag. The measured temperature at this stage was found to be 1500°C in front of the tuyere. One round took about 5 to 6 hours and preparation is made to take out the hot iron sponge.

- Removal of slag and handling of red hot sponge iron bloom: In case of bowl furnaces, generally the slag was allowed to get collected and solidified at the bottom of the furnace. In the case of other furnaces, it was tapped out through the slag hole known as 'Hagan.' After the smelting period was over, the bellows along with blow pipes were removed and the temporary wall for closing the front opening was removed and the partially melted tuyere was taken out with the help of a tong and a wooden pole. It was placed on a large granite stone anvil and hammered to consolidate and remove the molten slag filled in the pores.

- Secondary refining of the bloom: This most important and exclusive Indian practice was carried out to remove the slag trapped inside the iron block. For this, the iron bloom was reheated in a smithy forge to almost white hot (>1250°C) condition and silica sand was sprinkled upon it. This reacted with the remaining FeO and helped in forming fluid 2FeO.SiO2 slag which flowed out of the iron block. The iron block was taken out of the furnace and forged to increase its density. This process was repeated till the bloom was converted into 12 to 15mm square/circular rod. This refined rod containing 0.2 to 0.4% SiO2 almost free from the slag inclusion was cut into 150 to 180mm long pieces and sold to the blacksmiths or 'Lohars' for reshaping them into useful objects.

National Metallurgical Laboratory, Jamshedpur, in India made great strides in improving the ancient iron making process and made significant contributions to the iron industry.[15]

Wootz Steel

Wootz is the anglicized version of 'ukku' in the language of the states of Karnataka and Andhra Pradesh, a term denoting steel. Ample literary references suggest that the steel from southern India was the finest and once exported to Europe, China, Arab countries and the Middle East. Though an ancient material, it fulfills the description of advanced material. It is an ultra-high carbon steel of 1-2% exhibiting properties such as super-plasticity and high impact hardness.[16]

Wootz steel spurred developments in modern metallographic studies. Indian wootz ingots are believed to have been used to forge Oriental Damascus swords which were reputed to cut even gauze handkerchiefs and silk. Finest swords and artefacts of Damascus steel are seen in museums today.[16]

Although iron and steel had been used for thousands of years, the role of carbon in steel as the dominant element was found only in 1774 by the Swedish chemist, Tobern Bergman, and was due to the efforts of Europeans to unravel the mysteries of wootz. With the aim of reproducing the South Indian wootz steel on an industrial scale, there was a spurt in interest in many European travellers in early 1800's. By 1918 Belaiew made an important finding concerning wootz steel; he was probably the first to attribute the malleability of it to the spheroidized nature of the forged steel and to recognize that this occurs during forging at a temperature of red heat (700-800oC).[16]

References

- ↑ 1.0 1.1 1.2 1.3 1.4 Vibha Tripathi, Aspects of Iron Technology in India in Propagation, vol 3-1, 2012

- ↑ 2.0 2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 A. K., Vaish, Biswas P. K., Goswami N. G., Krishnan C. S. S., and Ramachandra Rao P. “Historical Perspective of Iron in Ancient India.” Journal of Metallurgy and Materials Science 42, no. 1 (January 2000): 65–74.

- ↑ Bag, A. K (1997) ed., History of Technology in India, Vol. 1, From Antiquity to c. 1200 A.D. New Delhi: Indian National Science Academy.

- ↑ Bose, D. M, et al., (1971) ed., A Concise History of Science in India. New Delhi: Indian National Science Academy

- ↑ 5.0 5.1 5.2 Prakash, B. "Ferrous Metallurgy in Ancient India" in Metallurgy in India: A Retrospective Ed. P. Ramachandra Rao, and N. G. Goswami. New York: India International Publisher (2001) 52-91

- ↑ Iron and Steel Industry in Ancient India by Satyendra

- ↑ 7.0 7.1 Dube, R. K. Ancient Indian Metallurgy in Vedic Heritage Portal (2015)

- ↑ Subrahmanyam, B.R. Iron age in India - Studies in material culture between 7th century BC and 1st century A.D. (1966) Acharya Nagarjuna University

- ↑ Shukla Yajurveda

- ↑ Prakash, S. (1965) Founders of Science in Ancient India, New Delhi: The Research Institute of Ancient Studies.

- ↑ Prakash, B., and Tripathi, V., (1986), Iron technology in ancient india, In Historical Metallurgy, September, pp. 568-579.

- ↑ 12.0 12.1 12.2 12.3 Metallurgy of Iron

- ↑ 13.0 13.1 Prakash, B. Ancient Iron Making in India in Iron & Steel Heritage of India Ed. S. Ranganathan, ATM 97, Jamshedpur

- ↑ Saravanan, R. Iron: From Metal to Metallurgy Heritage: Journal of Multidisciplinary Studies in Archaeology 5 (2017): 514‐518

- ↑ 15.0 15.1 15.2 A.K. Vaish, P.K. Biswas, S.P. Chaudhuri, M.M. Humane, R.K. Minz, B.A. Lakra, S.K. Sinhababu, P.K.De, N.G. Goswami, C. S. Sivaramakrishnan and P. Ramachandra Rao. Iron making in ancient India - A critical assessment in Tradition and Innovation in the History of Iron Making - An Indo-European Perspective eds., Girijā Pāṇḍe, Jan af Geijerstam (2002) Nainital: Pahar Parikarma

- ↑ 16.0 16.1 16.2 Srinivasan. S and Ranganathan. S. Wootz steel: An advanced material of the ancient world in Iron & Steel Heritage of India Ed. S. Ranganathan, ATM 97, Jamshedpur