Rasayana Shastra (रसायनशास्त्रम्)

| This article needs editing.

Add and improvise the content from reliable sources. |

Rasayana Shastra (Samskrit: रसायनशास्त्रम्) referred to the subject of Chemistry based on the chemical activities involved in biological and inorganic processes. It was also called Rasatantra, Rasa Kriya or Rasa Vidya roughly translating to 'Science of Liquids'. "Rasa" in ayurvedic terminology refers to mercury and Rasashastra exclusively deals with the treatment using mercury and its compounds. It is well known that science and technology in ancient and medieval India covered all the major branches of human knowledge and activities, including mathematics, astronomy, physics, chemistry, medical science and surgery etc.

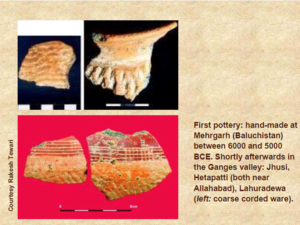

Chemistry is the study of elements present in the universe which involves the nature of the elements, their occurrence, their physical and chemical properties, their compounds, reactivity, uses and applications. Ancient samskrit literary works supported by the archaeological excavations all over the nation have proved the development of this science as early as the vedic period. The earliest evidence of chemical knowledge possessed by the ancient Indians in the prehistoric age has been brought to light by the findings of archaeological excavations in Baluchistan, Sindh and Punjab. The ruins of the Indus Valley Civilization that have been unearthed at in these areas furnish much information about the chemical knowledge acquired by the Indus Valley people, particularly with reference to the practical arts like pottery, brick-making, and extraction and working of metals.[1]

The findings testify to the facts that the people in the remote ages were acquainted with the art of making painted potteries as well as with the preparation and working of metallic copper. Prafulla Chandra Ray was a renowned researcher of chemistry, who set up several chemical industries in Bengal and is regarded as the "Father of Indian Chemistry" in modern times.

One must bear in mind that it is not just India, but several cultures, including non-western cultures around the world that have made several interesting innovations in the fields of chemistry and other subjects. However the present matter pertains to progress of Bharat in several areas of shastras and hence the attention is to bring such lesser known events to readers knowledge.

Introduction

Chemistry in ancient India, had its origin revealed through the great works of our ancient rishis can be attributed to three major areas[1]

- intellectual speculation about the nature and composition of matter (Alchemy)

- development of practical arts to meet the demand for the necessities of life (Dyes, Fermentation)

- self preservation and welfare measures of the society (Ayurvedic preparation)

Ancient India's contribution to science and technology include principles of chemistry which did not remain abstract but found expression in practical activities like fermentation processes, distillation of perfumes, aromatic liquids, manufacturing of dyes and pigments and extraction of sugar, extraction of oil from oilseeds, and metallurgy which has remained an activity central to all civilizations from the earliest ages. Archaeologists' findings of the Indus valley civilization showed a well developed urban system with public baths, streets, granaries, temples, houses with baked bricks, mass production of pottery and even a script of their own which depicted the story of early chemistry.[2]

In pottery making chemical processes were carried out in which materials were mixed, fired and moulded to achieve their objective. In the Rajasthan desert many pottery pieces of different shapes, sizes and colours were found. At Mohenjo Daro it was found that for the construction of a well, gypsum cement had been used which contained clay, lime, sand and traces of Calcium Carbonate (CaCO3) and was light grey in colour. Burnt bricks were manufactured on a large scale for making houses drains, boundary walls, public bath etc. Many useful products invented were plasters, hair washes, medicinal preparations etc. which had a number of minerals in them and were used by Indus Valley people.

Copper utensils, iron, seals, gold and silver ornaments, and terracotta discs and painted grey ware pottery have all been found in thirty five archaeological sites in North India. Scientific dating of these artifacts corresponds to the non-aryan invasion model of Indian antiquity.[2]

Thus the major chemical products that developed gradually over various eras can be summarized as glass, bricks and pottery, paper, soap, ink, dyeing, cosmetics and perfumes, alcoholic beverages, food processing, pharmaceuticals, mining techniques and alloy preparations, gun powder and saltpetre, and oilseeds.

Constitution and Properties of Matter

Chemistry involves the study of fundamental properties of matter and atoms, and their inter-relationships. The Ayurvedic period constitutes the most flourishing and fruitful age of ancient India relating to the accumulation and development of chemical sciences which at that time was closely associated with medicine. The physical and chemical theories were intricately associated with the srshti siddhantas propounded in the vedic, upanishadic and darshana shastras. Ayurveda was founded on the theories of cosmic evolution in Darshanas most importantly of Samkhya and Vaiseshika.[1]

Chemistry dealt primarily with the composition and changes of matter and the underlying principles were deduced in a systematic and logical way purely based on thoughts with little or no experimental proofs. Yet many such theories, the products of intellectual perfection and sublime intuition, stand in good comparison with some of the most recent and advanced scientific ideas of the present time. Here we come across a few ancient concepts with particular reference to srshti (theories of cosmogenesis) and origin of jagat (universe) with respect to matter and particles and their connection with chemistry.

- Rig veda (10.121.1) mentions Hiranyagarbha reflecting the concept of cosmic egg and origin of universe from an egg.

- Satapatha Brahmana (6.1.3.1-5) propounded a theory of material evolution.[3]

- Chandogya Upanishad mentions about expansion of universe from an embryonic stage called "Anda" (Chan. Upan. 3.19) wherein after period of one year, it burst open into two halves, one of silver and the other of gold. The lower half of silver became earth and the golden half became the sky and higher regions.

- Katha Upanisad (1.2.20) mentioned atoms and molecules.[3]

- Samkhya siddhanta (supported by Yoga sutras of Patanjali) describes the principles of conservation, transformation and dissipation of energy. Additionally the conception of space (desha) and time (Kala) are also discussed.

- Vaiseshika siddhanta propounded the particulate theory of matter (Padarthas) to describe the nature of different substances that make up this jagat.

- Prasastapada had proposed in his Padarthadharma-sarhgraha that atoms (anu) form - through dyads (dvyanuka) and triads, (tryanuka), gross bodies (`molecules' in modern terminology) and 'this gives rise to different qualities in a substance'.[3]

Thus broadly the origin and composition of matter had the foundations in our ancient texts.

Traditional Chemical Practices in India

The industries which sustained on chemical process may be classified broadly under the following headings.[4]

- Ayurvedic Preparations including mercurial compounds are discussed in Rasashastra and Rasayana.

- Pottery: Involves prolonged heating, fusion, evaporation, and treatment of minerals and pigments.

- Mineralogy (धातुशास्त्रम्) or the study of Minerals, broadly involves mining of Metal Ores such as those of Gold, silver, copper, lead, tin, zinc and iron and preparation of alloys such as bronze, and brass.

- Textile Technology (तन्तुकार्यम्)

- Building materials: Mortar and Cement using limestone, gypsum and their modified forms

- Fermentation Technology

- Extraction of Oils: Perfumes for cosmetics and consumption

- Chitrakarma (चित्रकर्म) or the art of painting used a variety of chemicals, mordants and pigments from vegetable and mineral sources.

- Dyeing: Numerous dyes from vegetable and mineral sources, use of mordants for textiles, craft paints

- Glass

Origin of Paints

Pottery and pottery-painting were practised in India ever since the dawn of civilisation. In archaeological parlance, pottery is regarded as index to culture; an alphabet to history. Generally it is studied typologically, a correlation with others, rather than extensive technological anaysis. However technological details such as - composition of clay, tempering agents, nature and components of the slips or glaze, nature of firing, porosity test and different chemical analyses - stand witness to not only the technological advancement of that culture but throws light on social, cultural, religious, economic, political aspects of that culture. Pottery both of fine and coarse types found in excavation sites of the Indian sub-continent are of many varieties, such as Red Ware, Buff Ware, Gray Ware, Black and Red Ware etc., broadly classified based on their colours.

Pottery - Preparation and Painting

People in very ancient settlements were well-acquainted with the art of making potteries of burnt clay and painting various designs on them. A large variety of ochres, haematites, pigments and organic colours were used by potters for painting the pots. This art of using pigments for beautification of pottery led to the development of paint technology in India.

Archaeological evidences of pre-historic settlements unearthed in various parts of India have revealed a large number of earthen ware items implying that the inhabitants of these early settlements were well-acquainted with the techniques related to pottery making, dye preparation and painting. It is interesting to note that regarding the pre-historic cultures, archaeologists have given a broad classification as Buff-ware culture and Red-ware culture based on the colours of the potteries distinctively found in those settlements. Potters' wheel was the characteristic implement of the Indus valley civilization.[5]

The characteristic ‘red and black’ pottery of Harappan civilization and a few polychrome potteries that have also been unearthed in these sites are painted in green and red on a buff slip. Chemical analysis revealed that red or Solomon colours in these objects are due to the presence of iron components in the clay. The slip of bright red colour is due to ferric oxide. The black and chocolate designs that are found painted on the body of the pottery owe their colour to oxides of manganese. The colouring agents used by the Indus valley people are used even today by potters. Many of the ancient techniques of selecting and applying colouring materials have come down to the present time also.[5]

Slip treatment was given to the pots before they were fired. Slipping serves two purposes it helps in closing the pores and provides smooth surfaces helpful in painting a design on them. Slipping was done by dipping the pot after burnishing in a solution or by painting with a solution formed by the finest portion of the clay used for making the pot or of any suitable materials such as ochres, pigments.

It is important to note that knowledge of colors and causal components were well known to the people. It is significant that the colors of these slips neither vanish nor fade in firing.

- Light pink shades - traces of iron in clay

- Dark pink - addition of red ochre in clay or as a slip directly

- Dark red - red oxide added to slip

- Yellow - addition of yellow ochre

Black and chocolate shades - manganiferous hematite was used (in combination if manganese is more produces pure back color, if iron preponderates it gives a chocolate color)

The technique of painting pots before firing and also painting designs on them after firing was in vogue. Mostly organic colours were used to paint the surfaces. For white pigment, lime, limestone, chalk and rice powder were used. To prepare black pigment, burnt coconut shell powder, soot, powdered charcoal, black iron oxide etc. were found to be used in some other settlements.[5]

During Vedic times and later on, ritual pots were painted with floral and geometrical designs in red, yellow blue and green colours. The solvent used for these pigments was plain water.

- Vermilion (mercuric sulphide) or dhau (ruddle) was used from red pigment

- Turmeric and yellow ochre was used for yellow colour

- Blue from indigo

- Green from leaves of particular trees and iron sulphate

- Grey was prepared from a kind of haematite

- Orange pigments were obtained by mixing red and yellow colours

- Copper sulphate was mixed with red pigment to obtain purple pigment

It is evident that methods like filtration, decantation, making pastes by rubbing on granite with little water, boiling with ingredients like calcium, catechu, soda etc, plant identification and collection of barks and leaves, and fermentation using rice starch were the adopted chemical processing techniques in preparation of pigments.[5]

Tinted Glass

Manufacture of glass and coloured glass is well documented in ancient literature such as Ramayana (2.90.27) (and other Buddhist texts), even though no glass objects have been recovered from Indus valley areas. Kautilya in his Arthashastra while laying down rules for the Superintendent of the treasury talks about the identification of various kinds of gems and precious stones and mentions a few times about glass; in the context of testing gems to place them in jewelry, in trade and tax payments, robbery and fines.[6]

- शेषाः काच-मणयः ।। ०२.११.३६ ।। (Arth. Shas. 2.11.36)[7] rest are the glass gems.

- क्षेपणः काच-अर्पण-आदीनि ।। ०२.१३.३८ ।। (Arth. Shas. 2.13.38)[8] Kshepana, guna, and kshudra ate three kinds of ornamental work. Setting jewels (kácha, glass bead) in gold is termed kshepana.[9]

- Evidence of trade of glass items[10]

Archaeological evidences support the use of glass beads, bangles, jars, tiles etc. made from 6th or 5th century' B.C. onwards. Most of the glass objects were coloured. Glass manufacture practiced as an indigenous industry in ancient India is seen in excavations particularly in the south (Arikamedu, Uraiyur). Along with this, the technique of colouring glass also developed. The glass specimens show that the glass makers of ancient India were highly competent in giving different colours and shades to glass objects.

Chemical analysis revealed, just like in the case of pottery, that colouring agents were obtained from the metallic ores. Different chemicals added to them finally led to attribute different shades of colours and glazes to the glass objects. Coloured glass was prepared by mixing silicates of soda, lime and appropriate metallic oxides[11]. Copper oxide, iron oxide, manganese oxides were generally used to give colours to the glass articles as for pottery. A special type of glass beads of 350 A.D. to 750 A.D. found at Ahicchatra is of gold foil glass. Layers of gold foils were poured in between two glass layers. All these prove that craftsmen in ancient India were highly skillful in the sophisticated technique of using metallic ores and chemicals as pigments in colouring very high temperature melting media like glass.

Chemistry in Minerals and Metals

Many processes involved in extraction of metals from ores to their purification deal with advanced knowledge of chemistry. Many ancient and medieval texts reveal that people had this knowledge as outlined below.[3][12]

- Rasashastra: The development of Rasashastra took place with regards to the processing and the use of heavy metals such as mercury, metals, minerals and many of their compounds for alchemical as well as therapeutic purposes. Many new methods/procedures/techniques for the treatment of mercury, metals/minerals were developed to convert these into pharmaceutically most suitable forms/compounds which are non-toxic, highly absorbable and most effective in therapeutics. Alchemical experiments (Lohavedha) were initially explored to remove poverty from the world by the monk of Buddhist order, Nagarjuna and his followers.[13]

- Therapeutic Potential: Although alchemic purposes of minerals were popular in earlier days, as Ayurveda developed utility of metals and minerals in therapeutics became prominent as seen in Charaka and Sushruta samhitas. Acharya Charaka mentioned three Maharasas (Makshika, Shilajatu and Sasyaka) and all eight Uparasas (Kankushta)[14] in his classic text. Interestingly, information on Sadharana rasas was not found in the classic. In addition to these minerals; information on certain salts (lavana dravya), alkaline substances (ksara dravyas) and calcium containing material (jantava dravya) etc. are also found described.[15]

- Chemical Apparatus: A large number of equipment, crucibles, furnaces etc., for processing of minerals and metals are described (Rasarnava). Rasaratnasamucchya contains description of several kinds of crucibles made of fireclay (vahnimrttika), funaces, implements and equipment to be used in the alchemical laboratory.

- Flame tests: Specific colors of flames are due to specific salts of copper, tin, lead (Rasarnava 49). This test is also practiced in present day as preliminary test to identify the chemical compounds.

- Extraction of Copper: Procedures were described for making copper metal from makshika (7.12-13) vimala (7.20-21) sasyaka (7.41-44) in Rasarnava text. While makshika and vimala are identified as pyrites (Copper pyrite ores) sasyaka is copper sulphate. All three products yielded Tamra or copper. Copper was discovered long before the Daltonian chemistry came into existence.

- Corrosion: Six metals were arranged in the increasing order of corrosion (Rasarnava 7.89-90) - gold, silver, copper, iron, tin and lead. Sulphur was highly reactive with most of the metals.[3]

- Chemical Processes: Reduction-Oxidation in mineral-metal-metaloxide systems, conversion to sulphides were described in Rasaratnasamucchaya text. For preparation of pharmaceutical grade products for human consumption, many intermediary operations were described: purification of the mineral, metallic extraction (satvapaatana), liquefaction, distillation, incineration etc were performed.

- Preparation of Alloys: Mishra-loha or mixed metals were prepared. Alloys of five metals (Pancha-loha) which is used till date to prepare auspicious idols and eight metals (ashtadhatu) were developed.

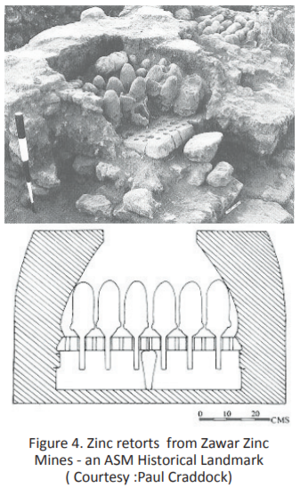

- Zinc Technology: The Zawar zinc technology produced high-zinc (28%) brass alloy not produced anywhere else in the rest of the world. It is the earliest firm evidence for production of metallic zinc in the world. The zinc retorts found in Zawar were similar to those described in Rasaratnasamucchyaa and by Nagarjuna in his Rasaratnakara. The text gives details of the distillation process of zinc by tiryakpatanayantra (distillation by descending) which is totally an ingenious method where the zinc vapor formed after smelting zinc ore (in specifically designed retorts with condensers and furnaces) could be drastically cooled down to get a melt that could solidify to zinc metal.[12]

- Bidri Alloy: The alloy produced in the South Indian town of Bidar, contained Zinc (76-98%), Copper (2-10%), at times Lead (1-8%), tin (1-5%) and trace of Iron. Darkening of the Bidriware made was done by applying a paste of ammonium chloride, potassium nitrate, sodium chloride and copper sulphate. Several impressive vessels, ewers, pitchers, vessels and huqqa bases were made of bidri ware with patterns influenced by the fine geometric and floral patterns and inlayed with gold and silver metals.

Fermentation Technology

Fermentation is a particular method of digesting of relected substances that leads to chemical transformation of organic substances into simpler compounds by the action of fement.[16]

Generally fermentation quickly sets in substances of high sugar-content. Hence fermentation technology started in different parts of the old world with sweet-substances, be it vegetable or animal product. In Egypt honey was utilized first for preparation of intoxicating drink by fermentation. In Bharat, Soma juice, a sweet substance formed the first article of fermentation by the Vedic people. Although the technique or art of fermentation has been "self generated", the process may have been observed and used in remote past.

Milk products, like, curd (dadhi) requiring fermentation for changing of milk into such coagulated substance, was a very popular food article even in the Rigveda. The technique of curdling milk occurs in a number of texts connected with the Yajurveda. In the rituals Soma juice preparation involved preparing a sweet concoction for divine offering; while "sura" was another noted fermented product (a product of cereal and honey).

References

- ↑ 1.0 1.1 1.2 Ray, P. (1956) History of Chemistry in Ancient and Medieval India, incorporating the History of Hindu Chemistry by Acharya Prafulla Chandra Ray. Calcutta: Indian Chemical Society

- ↑ 2.0 2.1 Purwar, Chhavi. Significant Contribution of Chemistry in Ancient Indian Science and Technology. International Journal of Development Research Vol. 06, Issue, 12, pp.10784-10788, December, 2016

- ↑ 3.0 3.1 3.2 3.3 3.4 Minerals and Their Exploitation in Ancient and Pre-modern India by Prof. A. K. Biswas

- ↑ Danino. Michel, Technology in Ancient India

- ↑ 5.0 5.1 5.2 5.3 Krishnamurthy. Radha, (1997) History of Technology in India, Vol. 1, From Antiquity to c. 1200 A.D. New Delhi: Indian National Science Academy. (Chapter Dyes, Mordants and Pigments: Pages 309 - 312)

- ↑ Krishnamurthy. Radha, (1997) History of Technology in India, Vol. 1, From Antiquity to c. 1200 A.D. New Delhi: Indian National Science Academy. (Chapter Dyes, Mordants and Pigments: Page 312)

- ↑ Arthashastra (Adhikarana 2 Adhyaya 11)

- ↑ Arthashastra (Adhikarana 2 Adhyaya 13)

- ↑ Shamasastry. R, Kautilya's Arthashastra with English Translation (Page 120)

- ↑ Shamasastry. R, Kautilya's Arthashastra with English Translation (Page 343)

- ↑ Jaggi, O.P. (1977) Science and Technology in Ancient India, New Delhi. Vol I, p.203

- ↑ 12.0 12.1 Srinivasan, Sharada and Ranganathan, Srinivasa. (2013) Minerals and Metals Heritage of India. Bangalore:National Institute of Advanced Studies.

- ↑ Joshi, Damodar. (1997) History of Technology in India, Vol. 1, From Antiquity to c. 1200 A.D. by A. K. Bag. New Delhi: Indian National Science Academy. (Chapter Mercurial and Metallic Compunds: Page 256)

- ↑ Charaka Samhita. Ayurveda Dipika Commentary by Chakrapanidutta. Varanasi: Chaukhambha Surbharati Prakashan (2000). (Chikitsa Sthana 7/111 pp 456).

- ↑ Chandrashekhar. J., et. al., Therapeutic Potentials of Minerals in Ancient India : A Review through Charaka Samhita. J Res Edu Indian Med, Jan - Mar 2014; Vol. XX (1): 9-20

- ↑ Mira Roy. (1997) History of Technology in India, Vol. 1, From Antiquity to c. 1200 A.D. by A. K. Bag. New Delhi: Indian National Science Academy. (Chapter Fermentation Technology : Page 437)