Difference between revisions of "Mineralogy (धातुशास्त्रम्)"

(→रसः ॥ Mercury: added content and references) |

(added category) |

||

| Line 341: | Line 341: | ||

== References == | == References == | ||

<references /> | <references /> | ||

| + | [[Category:Shastras]] | ||

Revision as of 21:10, 15 August 2022

| This article needs editing.

Add and improvise the content from reliable sources. |

Mineralogy (Samskrit: धातुशास्त्रम्) or metallurgy discusses the chemistry of Dhatus (minerals), their properties, composition, reactions, combination products namely alloys and their uses. A related topic, mining of metals, involves the chemistry of extraction from ores, smelting and forging activities. History of mining in the Indian subcontinent can be traced back to pre-Harappan period where the evidence of earliest settlements of farming communities using metal implements have been found.[1]

Bharatavarsha is known for its use of gold and silver for jewelry and making ornamental vessels for domestic use with silver. Copper tools, such as axes, sickles are found in many archaeological sites indicating that many farming tribes and agricultural communities were using them. Metallurgy of copper and its alloys (brass and bronze) was highly developed during this period. A remarkable use of brass was made in the constructional work of an unfinished Vihara made near Nalanda (Bihar). Thus many archaeological revelations have unearthed valuable knowledge pertaining to sulbashastra (geology) and dhatushastra (metallurgy) of the ancients.[1]

Introduction

Metals, Minerals and ores are mentioned by the terms dhatu (धातुः) khanija (खानिजम्) and the chemistry involved is termed Khanija-rasayana (खानिजरसायनम्). A mineral is defined in modern terms as follows[2]

"As we knew mineral is a naturally occurring crystalline element or a compound having definite chemical composition, and formed as a product of inorganic processes."

The scientific analysis of the archaeological and literary evidences points to the debunking of the aryan invasion myth in the recent times.[2]

A number of experts have concluded that the collapse of the Harappan civilization was not on account of any 'foreign invasion' but essentially due to repeated floods, tectonic movement leading to the drying up and disappearance of the Sarasvati river, civil war, loss of trade etc.

Just like pottery, metals in antiquity is also linked to the history of a civilization. In the ancient past, the first metals to be utilized were those found in the native or elemental state, and then progressively those metals were used which could be easily extracted or smelted from their ores. The smelting of metals, which were more difficult to extract from ores, was mastered later. Most of the metals and elements indicated in the Periodic Table were in fact identified only in the last few centuries.

Alchemy was one of the chief areas for the exploration of mercurial compounds, as specialists in medicine like Charaka, believed in the search for the ideal rasa or elixir which could prolong life indefinitely. They believed in therapeutic values of organic as well as inorganic materials such as metals and metallic compounds; they also aspired to convert base metals into gold. This alchemical dream was boosted when Nagarjuna claimed (Rasaratnakara - 1.3) that zinc ore roasted thrice with copper converts the latter into 'gold'. However, it was gold-like, brilliant yellow brass that came into existence.[2]

Many textual evidences which speak about gems, minerals and metals include the Rig and Yajurvedic references of antiquity, while early pre-christian era texts such as Kautilya's Arthashastra deal extensively about the ratnas or gems apart from other untraced books like Mahakala or Vyaadi. Rasaratnakara of Nagarjuna traced to 2nd century A.D. and Brhat Samhita of Varahamihira of 5th century throw light on many aspects of ratnapariksha. The pre-modern texts like Vagbhata's Ashtangahridaya, Rasarnava (12th Century A.D.), Ratnapariksha by Buddhabhatta, Rasaratnasamucchaya and Agastimata are exclusive medieval texts which are quite valuable even in present day to adapt and improvise the chemical techniques followed in the present day.

Minerals in Vedas

Naturally Bharat's exploration for minerals and metals used in the past started with the Rigveda, the world's oldest literature. In the Rigveda we find some concern for digging and mines (khanitra), mining treasure (nidhi) and gems (mani, ratna) etc. Conch-shell (sankha) and conchpearl (krshana) were quite popular. Ayas (अयस्) in the Rigveda meant 'metal' in general and not 'iron' in particular which the scholars mention was a later discovery. Ayasi or metallic equipments in the Rigvedic texts were probably made of copper and its alloys such as bronze. Various implements and artefacts made of copper, bronze, and ornaments made of gold and silver are described.[2]

Mention about metalsmith (कार्मारः) is made in Rigveda (9.112.2)

कार्मारो अश्मभिर्द्युभिर्हिरण्यवन्तमिच्छतीन्द्रायेन्दो परि स्रव ॥२॥ (Rig. Veda. 1.191.15)

A furnace, blower and fire - the setup used by a metalsmith has been described. Fire is described as a 'cradle of gems' that melts gold and the blower (ध्मातरी dhmaatari) or metalsmith blows to produce sharp flame in a furnace.

यदीमह त्रितो दिव्युप ध्मातेव धमति शिशीते ध्मातरी यथा ॥५॥ (Rig. Veda. 5.9.5)

Shatapatha Brahmana introduces the word "bhastraa" meaning a leather bellow used to blow air into a furnace (1.1.2.7, 1.6.3.16). Yajurveda was the first literature to mention gold (हिरण्यं), "shyaamaayasa (श्यामं)" or "krshnaayasa" which is black metal or iron specifically, loha or red metal copper (लोहं), sisam or lead (सीसं) and trapu or tin (त्रपु) in the Rudrachamaka, clearly mentions the production of metals from yajna. Agni clearly has a vital role in the extraction and working of metals.

हिरण्यं च मे यश् च मे श्यामं च मे लोहं च मे सीसं च मे त्रपु च मे यज्ञेन कल्पन्ताम् ॥ (Shuk. Yaju. Veda. 18.13)

Atharvaveda describes the genesis of the shankha (conch) and mukta (pearl) in the oceans.

दिवि जातः समुद्रजः सिन्धुतस्पर्याभृतः । स नो हिरण्यजाः शङ्ख आयुष्प्रतरणो मणिः ॥४॥ (Athar. Veda. 4.10.4)[3]

Summary: This Atharvaveda sukta (4.10.1-7) extols the greatness of shankha as the precious gem which has taken birth from Vayu, Antariksha and other mandalas as the remover of all papa (sins) and protector from all kinds of ailments, remover of poverty and unforseen disasters. Shankha first arose in the celestial worlds and then from the oceans on earth.[4] Chandogya Upanisad recognised that metals have intrinsic properties irrespective of the shapes that these may assume (Cha. Up 6.1.5 & 6). It stipulated that one can join gold with the help of borax, lead with the help of tin 'etc.

तद्यथा लवणेन सुवर्णँ सन्दध्यात्सुवर्णेन रजतँ रजतेन त्रपु त्रपुणा सीसँ सीसेन लोहं लोहेन दारु दारु चर्मणा ॥ ७ ॥ (Chan. Upan. 4.17.7)[5]

Summary: Just as one would join together (pieces of) gold by borax, by gold silver, by silver tin, by tin lead, by lead iron, by iron wood or by leather.[6]

Arthashastra defines the following as metals

काल-अयस-ताम्र-वृत्त-कंस-सीस-त्रपु-वैकृन्तक-आर्कूटानि लोहानि ।। ०२.१७.१४ ।।

Káláyasa (iron), támra (copper), vritta (?), kámsya (bronze), sísa (lead), trapu (tin), vaikrintaka (mercury ?), and árakuata (brass), are metals.[7]

It is interesting to note that ancient texts have mentioned many matters regarding the existence and usage of metals, their properties, nature and their extraction. Debiprasad Chattopadhyaya acclaimed Uddalaka Aruni as 'the first scientist in the world'. Uddalaka Aruni as mentioned in the Chandogya Upanishad propounded that everything in the universe including man evolved out of three elements, and even mind is a product of matter. According to Chattopadhyaya Maharshi Uddalaka preceded Theles of Greece by nearly two centuries.[2][8]

Gem - Minerals

Earliest complete description of the gems is given in texts such as Arthashastra and Brhat Samhita.

वज्रैन्द्रनील-मरकतकर्केतरपद्मरागरुधिरऽख्याः । वैदूर्य[क्.वैडूर्य]पुलकविमलकराजमणिस्फटिकशशिकान्ताः ।।

सौगन्धिक-गोमेदक-शङ्ख-महानील-पुष्परागऽख्याः । ब्रह्ममणि-ज्योतीरस-सस्यक-मुक्ता-प्रवालानि ।। (Brht. Samh. 80.4-5)

Meaning: The following are the gems: Vajra (Diamonds), Indranila (Sapphire), Marakata (Emerald), Arkata (Agate), Padmaraga (Ruby), Rudhira (Blood-stone), Vaidurya (Beryl), Pulaka (Amethyst), Vimalaka, Rajamani, Spatika (Quartz), Shashikanta (moon-gem), Saugandhika, Gomedaka (Zircon), Shankha (Conch Shell), Mahanila (Azure), Pushparaga (Topaz), Brahma-mani, Jyoteerasa, Sasyaka, Mukta (Pearl), Pravala (Coral).[9]

Origin

There are many legends about the origin of metals and gems in the vaidika vangmaya. Many puranas discuss about the origin of gold from the semen of Shiva.

Ratnapariksa and Agastimata narrated the legend that gems had been derived from the body of the slain demon Bala: diamond from his bones, pearl from the teeth, ruby from the blood, sapphire from the eyes, emerald from the bile etc. The mythical bird Garuda had taken the green bile of the demon in its mouth and then vomitted it (hence the name Garutmata and Garudodgaara) on a mountain on the sea- coast near a desert 'beyond Barbara country’. Both Ratnapariksha and Agastimata mentioned Garuda as the ruler of the serpents hence called pannagadhipah. Panna also means something fallen down or dropped. Thus, the dropped bile or the green emerald also came to be known as panna.[10]

In his Brhat Samhita, Varahamihira gave a scientific explanation that the gems were caused by the characteristic qualities of the earth.

रत्नानि बलाद्दैत्याद्दधीचितोऽन्ये वदन्ति जातानि । केचिद्भुवः स्वभावाद्वैचित्र्यं प्राहुरुपलानाम् ।। (Brht. Samh. 80.3)

Meaning: Gems, they say, were born of the bones of the daitya Bala; while others state that they were born of Dadichi; yet others say that the wonderful variety of germs is caused by the characteristic qualities of the earth.[9]

Samskrit Etymological Roots

The names of many minerals and elements that we find in European languages were originally derived from Samskrit, having strong etymological roots. A few samskrit origins of minerals are as follows.[10]

- Corundum is derived from "कुरुविन्दः । kuruvinda", meaning that which abrades.

- Sulphur was derived from "शुल्वारी । Shulvari" meaning that which is enemy (अरिः) of, or reacts with, copper (शुल्वा। Shulva).

- Beryllium is derived from mineral Beryl. Beryl is derived from the term वैदूर्यम् । Vaidurya or the South Indian term "Veluriya". Panini mentions in his Ashtadhyayi (4.3.84) that the mineral came from Vidura (विदूर) locality in South India (hence termed Vaidurya), identified as Salem district, supported by evidence that mines of Coimbatore used to supply beryl for its export to the Romans. Outside India, Veluriya was called Beryllos (Greek) and Beryllus (Latin) from which the English term Beryl and Beryllium came forth.

- Emerald - 'मरकतम् । Marakata' in Samskrit gave rise to smaragdos in Greek, smaragdus in Latin, esmeralda in Spanish and emerald in English. Emerald has few more name - equivalents in Sanskrit: Harinmani (green gem), Garudodgdra, Garutmata, Panna etc.

The identity of vaidurya with beryl is well- established. It was known to be quite different from cat’s eye. Kautilya listed beryl vaidurya and cat’s eye marjdraksaka as distinctly separate gems (AS 2.11.30 and 39).

| Name

English |

Name

Samskrit |

Colour | Reasons for non-white

colour |

|---|---|---|---|

| Diamond | Vajra (वज्रः) | Colourless | Blue due to boron, yellow/green due to nitrogen |

| Corundrum | Kuruvinda (कुरुविन्दः) | Colourless | Pure Al2O3 is colourless |

| Ruby | Padmaraga (पद्मरागम्) | Red | Cr3+ (Chromium ion) replaces Al3+ (Aluminium ion). Transition involving ligandfield effect. |

| Sapphire | Indranila (इन्द्रनीलः) | Blue | Four different mechanisms including charge transfer, combination of Fe (Iron) and Ti (Titanium) |

| Chrysoberyl/Cat's eye | Marjarakshaka / Lasunia | Green/ Yellow | Green due to Cr and yellow due to Fe substituting in BeAl2O4 structure |

| Spinel/Balas-ruby | Balasuryaka | Rose-red | Pure spinel Mg Al2O4 is colourless. Cr3+substitution makes it rose-red. Fe and Mg may further alter the colour. |

| Topaz | Pushparaga (पुष्परागः) | Yellow | Pure topaz is colourless [Al (F,0H)]2 SiO4. Yellow colour is due to impurities - ferrous oxide, lime and alkali. Dichromic is blue. |

| Beryl | Vaidurya (वैडूर्यम्) | Faint Green, Water colour | Pure beryl Be3Al2Si6O18 is colourless. Faint green due to substituting Cr3+. This is allochromatic effect - transition involving ligand field. |

| Emerald | Marakata (मरकतक) Panna | Deep grass green | This is beryl containing more Cr3+ imparting green colour. Dichroic, the second blueish colour is due to iron. |

| Aquamarine | Paribhadra | Faint blue to bluish green | Bluish tinge due to iron. |

| Zircon | Gomedhaka (गोमेदकः) | Cow-flesh color | Pure zircon ZrSiO4 is colourless. Reddish-yellow colour of Hyacinth is due to Fe3+ decolourised on reduction to Fe2+. |

| Garnet | Tamrya or Tamdi | Various colors | Family of minerals M2+3 M3+2(SiO4)3. Colour depends upon chemical composition. Hessonite is confused with Hyacinth. Colour due to iron. |

| Tourmaline | Vaikranta | Various colors | H9Al3(B.OH)2 Si4O19 pure tourmaline is light coloured. Fe2+ and Cr3+ make it dark green. Mg makes it brown and Mn dark red. |

| Quartz | Sphatika (स्फटिकः) | Colourless | Pure SiO2 is colourless. Yellow citrine due to iron green chrysoprase due to nickel, violet amethyst due to manganese etc. |

| Agate | Akik | Light colour | Hydrated SiO2 is colourless. Hydrated ferric oxide as impurity makes it brown or yellow. |

| Carnelian | Rudhirakhya (रुधिर) | Red | Heating causes dehydration and ferric oxide gives red colour to carnelian. |

| Olivine/ Chrysolite/ Peridot | Puttika / Jabarjad | Bottle green | Pure Mg2SiO4 is colourless Replacement of part of MgO by ferrous oxide makes it yellowish green. Mn2+ Ni2+ further change the colour. |

| Orthoclase/Feldspar

Moonstone Sunstone |

Moonstone (शशिकान्तः । Chandrakanta) Sunstone (Suryakanta) | Opalescent play of

colour |

Interference of light from thin layers. |

| Jade | Pitu | White green black | Green due to Mn and Cr and Fe2+. Black due to Fe3+ |

| Pearl | Mukta (मुक्ता) | Usually white | Iron, manganese etc.possibly complexed with organic matter, so that the colour is perishable on heating. |

| Coral | Pravala (प्रवाला) / Vidruma | red, black | Iron, manganese etc.possibly complexed with organic matter, so that the colour is perishable on heating. |

The Eight Metals of Antiquity

A few non-gem minerals or metals of commercial importance in ancient India: include the following list:[10]

adrija (bitumen), abhraka (mica), kajjali (cinnabar), karpurarasa (calomel), kamksi (alum), kasisa (green vitriol or ferrous sulphate), kharpara (zinc ore), gandhaka (sulphur), gandhara (red lead), chulika lavana (sal ammoniac), tankana (borax), tala (orpiment), tutthaka (blue vitriol), nilanjana (stibnite), makaradhvaja (mercuric sulphide), manahsila (realgar) maksika (pyrite), swarnamakshika (chalcopyrite), mrddarasrnga (anglesite or litharge), rasaka (calamine), rasakarpura (mercuric chloride), rasasindura (mercuric sulphide), rasanjana (stibnite), varatika (marine nodule), vahnimrttika (fire-clay), vimalaka (pyrite), kamsya vimala (arsenopyrite), silajatu (bitumen), sarjika mrttika (river-bed alkaline reh), sasyaka (blue vitriol), sisaja (red lead), suvarcika (borax), srotanjana or sohta (carrollite), haritala (orpiment) etc.

The present section reviews the important metals, their qualities, ores and interesting points about their role since ancient times. One of the ancient texts that gives a comprehensive view about metals is Kautilya's Arthashastra. Though a book on polity and administration, it gives a great deal of information regarding many aspects of life such as agriculture, economy, trade, metals and gems, occupations, weapons and spies and many other interesting out of the norm situations. A summary of the description of the ores, management of mines, rock veins of minerals, metals (gold silver copper and their alloys) with their extraction and working, as well as of alloys, information of fabrication of metallic artefacts are found in the text. Kautilya outlines the duties of the Superintendent of Mines (लोहाध्यक्षः) and gives him the details of the ores of metals and their fabrications in Adhyaya 12 of Adhikarana 2. Some common observations about the ores are also mentioned by Kautilya such as

सर्व-धातूनां गौरव-वृद्धौ सत्त्व-वृद्धिः ।। ०२.१२.०७ ।। (Arth. Shast. 2.12.7)[11]

The heavier the ores, greater will be the quantity of metal in them (sattva-vrddhi)

The commonly used eight metals in antiquity are gold, silver, copper, iron, tin, lead, zinc and mercury.[12]

सुवर्णम् हिरण्यम् वा ॥ Gold (Aurum - Au)

Arthashastra describes the qualities of the gold ore thus

पीतकास्-ताम्रकास्ताम्र-पीतका वा भूमि-प्रस्तर-धातवो भिन्ना ..... बहुफेनधूमाश्च सुवर्ण-धातवः प्रतीवाप-अर्थास्ताम्ररूप्य-वेधनाः ।। ०२.१२.०५ ।। (Arth. Shast. 2.12.5)[11]

"Those ores which are obtained from plains or slopes of mountains; which are either yellow or as red as copper or reddish yellow; which are disjoined and marked with blue lines; which have the colour of black beans (masha, Phraseolus Radiatus), green beans (mudga, Phraseolus Mungo), and sesamum; which are marked with spots like a drop of curd and resplendent as turmeric, yellow myrobalan, petals of a lotus, acquatic plant, the liver or the spleen; which possess a sandy layer within them and are marked with figures of a circle or a svastika; which contain globular masses (sagulika); and which, when roasted do not split, but emit much foam and smoke are the ores of gold (suvarnadhátavah), and are used to form amalgams with copper or silver (pratívápárthasté stámrarúpyavedharáh)".[13]

Early reference to gold is to be found in the Rigveda samhita. However, not many gold artifacts dating to Pre-Harappan period have been reported although in Rgveda Gold and its alloys with Ag and Cu have been mentioned in many places, such as, 1-85.9, 88.5, 67.3; II-37.9; V-54.15, 57.1, 60.4; VIII - 7.27-32 etc. In Vedic literature this metal has been mentioned as Hiranya (हिरण्यम्) probably because of its high corrosion and oxidation resistance and the practice of its preservation through generations.[14]

A noble metal, gold, is found in the native state, and was used to make jewellery and sheet metal due to the great ductility and lustre of the pure metal. In human civilization it has been named as the most sinister and deadly metal although due to its ductility and softness it had proved worthless for making any war weapon.

Extraction Process

- Gold Ore : Native metal associated with silica and soil.

- Gravity separation or panning.

- Amalgamation technique with Mercury

When a pan containing the suspension is agitated under water, gold particles separate and settle at the bottom of the pan, while sand and soil are washed away. This is the simple gravity separation process. The second process known to ancient craftsmen is that of amalgamation with Mercury and recovery of gold by evaporation and distillation of mercury. The technique of Hg amalgamation and gilding was thus well known to the Indian craftmen from the very early times.[14]

In ancient times, gold was collected by panning alluvial sands from placer deposits. However, India has the distinction that the deepest ancient mines in the world for gold come from the Maski region of Karnataka with carbon dates from the middle of the first millennium BC.[12]

- Oldest literary reference to usage of Gold in Rigveda

- World's deepest gold mines are found in Karnataka state of India

- Process of preparing alloys is ancient

रजतः ॥ Silver (Argentum - Ag)

Arthashastra describes the qualities of the silver ore thus

शङ्ख-कर्पूर-स्फटिक-नव-नीत-कपोत-पारावत-विमलक-मयूर-ग्रीवा-वर्णाः ... न स्फुटन्ति बहु-फेन-धूमाश्च रूप्य-धातवः ।। ०२.१२.०६ ।। (Arth. Shast. 2.12.6)[11]

"Those ores which have the colour of a conch-shell, camphor, alum, butter, a pigeon, turtle-dove, Vimalaka (a kind of precious stone), or the neck of a peacock; which are as resplendent as opal (sasyaka), agate (gomédaka), cane-sugar (guda), and granulated sugar (matsyandika) which has the colour of the flower of kovidára (Bauhinia Variegata), of lotus, of patali (Bignonia Suaveolens), of kalaya (a kind of phraseolus), of kshauma (flax), and of atasi (Dinuin Usitatissimum); which may be in combination with lead or iron (anjana); which smell like raw meat, are disjoined gray or blackish white, and are marked with lines or spots; and which, when roasted, do not split, but emit much foam and smoke are silver ores."[13]

Unlike gold, the brilliant white metal, silver, has been introduced relatively late in the civilizations largely because of its non-availability in the nature as native metal. It is rarely found in nature as virgin metal and is found associated with lead ores such as galena. A domestic metal, similar to gold, silver has no value in armoury or warfare. Archaeologically, only few silver artifacts have been found dating back to Harappan times, however, the Vedic period has quite some instances of usage of this metal.[14]

Extraction Process

- Silver Ore : Cerasgerite (AgCl) and Argentite (Ag2S) associated with Galena (Lead ore) and/or Sphalerite or mixed sulphide ores.

- Roasting and reduction smelting techniques for the treatment of sulphide

- Purification of Silver by Cupellation.

During the extraction of lead from its ores, Argentite also gets decomposed and reduced easily to readily form an alloy with metallic lead. Pure silver subsequently produced by the process of cupellation. Some scholars mention that these processes were known during the Harappan period. Silver metal is obtained from the alloy of Pb-Ag by reheating it in a shallow hearth furnace having the bottom prepared with bone charcoal. During remelting of the alloy it is subjected to oxidizing condition by blowing excess air when lead gets preferentially oxidized to PbO (litharge) which has a very low melting point. This molten litharge is skimmed off and partially absorbed by the furnace hearth. This process is known as ‘Cupellation'.[14]

The shining white colour, high ductility, high corrosion resistance and the non-tarnishing properties of silver attracted the attention of the primitive men and they found its use in making ornaments, utensils, decorative pieces and other house hold articles. It was popular as a coinage metal in the later periods after the smelting process was well established. Silver has been used in Ayurveda for its medicinal properties.

Interestingly, as far as silver production goes, the Aravalli region in North-West India ranks amongst the few major ancient silver producing sites in the world.

सीसम् ॥ Lead (Plumbum - Pb)

Arthashastra describes the qualities of the lead ore thus

काक-मोचकः कपोत-रोचना-वर्णः श्वेत-राजि-नद्धो वा विस्रः सीस-धातुः ।। ०२.१२.१३ ।। (Arth. Shast. 2.12.13)[11]

"Those ores which have the colour of kákamochaka (Solanum Indica), pigeon, or cow‟s bile, and which are marked with white lines and smell like raw meat are the ores of lead."[13]

The lead artifacts during the Harappan period reflect the fact that people were acquainted with lead ores (such as galena) and their smelting process which is simple on account of easy reducibility and low melting point of the metal. Like gold and silver, lead did not find extensive usage in tools and implements owing to its softness. It is one of the softest and heaviest metal having shining grey lustre which leaves a black streak on paper. It is so soft that it can be scratched even with nail hence it’s use has been mostly for the manufacture of cheap jewellery dies or pattern for shaping other metals, and as a hardner in copper alloys.

Extraction Process

- Lead Ores : Galena (PbS), Litharge (PbO), Cerussite (PbCO3)

- Roasting and reduction smelting techniques for the treatment of sulphide

- Preferential Oxidation of lead to PbO (Litharge)

- Removal of pure Silver by Cupellation.

- Reduction of Litharge to produce metallic lead

Since liquid lead readily alloys with silver one of its major use was to first produce this alloy by coreduction of Pb and Ag minerals and then produce pure Silver by the process of cupellation. Litharge which has a low melting point is skimmed off and reduced in an ore hearth furnace to recover metallic lead.

Lead was commonly alloyed with copper and bronze for making die castings. Lead compounds also have been used for glazing potteries and in the manufacture of glass. It was used to prepare Pb-Sn alloy used as solder to join pieces of copper and bronze. In more recent centuries lead has been extensively used for preparing projectiles for slings and catapults, bullets, cannon balls and cast shots etc.

The mineral-rich Aravalli region of Rajasthan was one of the important early lead mining regions in antiquity.

- Lead was used in making alloys of silver, copper etc

- Chief coinage metal around 1-2nd BCE.

ताम्रम् ॥ Copper (Cuprum - Cu)

Arthashastra describes the qualities of the Copper ore thus

भारिकः स्निग्धो मृदुश्च प्रस्तर-धातुर्भूमि-भागो वा पिङ्गलो हरितः पाटलो लोहितो वा ताम्र-धातुः ।। ०२.१२.१२ ।। (Arth. Shast. 2.12.12)[11]

Those ores which are obtained from plains or slopes of mountains; and which are heavy, greasy, soft, tawny, green, dark, bluish-yellow (harita), pale-red, or red are ores of copper.[13] This description seems to refer to copper pyrites (yellow), cuprite (red) and malachite (green).

Mentioned as Lohitya and Loha in the Vedas, this metal has gained adequate attention after gold and silver by providing new weapons for fighting and self-protection marking the beginning the Copper Age. It may be noted that none of the metals such as gold, silver and lead were suitable for the production of tools and implements for warfare and protection. Man moved from the use of stone and clay, to fabricate his hunting tools and domestic utensils, to using metal for his needs with the advent of Copper mining. Copper, bright red colored, soft metal, is very ductile in nature, easily cold or hard worked to give any shape like rod, plate, wire and sheets. Apart from decorative uses, it was used for covering the wooden surface and engraving it for decoration and preservation of wood panels.

Extraction Process

- Copper Ores : Malachite (CuCO3.Cu(OH)2), Azurite (2CuCO3.Cu(OH)2), Cuprite (Cu2O), Chalcopyrite (Cu.FeS2) (most commonly found in India), Hydrated Blue Vitriol (CuSO4.5H2O)

- Roasting and Reduction methods using small shaft furnaces, with precise control of the thermochemistry

- Rasaratnasamucchaya mentions a processes for obtaining pure copper by smelting, using lemon juice as the reductant.

- Another process mentioned in the same text - Precipitation of Cu from blue vitriol solution by the process of cementation, to obtain copper bhasma for Ayurvedic uses

Early copper artifacts are reported from the pre-Indus valley sites of Baluchistan, the northwestern part of Indian subcontinent. Evidence of ancient mining of copper ores was from the Khetri region of Rajasthan in India dating to about 3rd-2nd millennium BC. Huge quantities of copper objects such as blades, arrow-heads, fish hooks were found from the sites of Pre-harappan excavations. It may be asserted based on evidence that copper metallurgy was developed indigenously in the Indian subcontinent well before 4000 BC. This theory of indigenous discovery of copper production technology is further supported by the presence of 4.8% Nickel and 2.14% lead in the copper, artifacts found at the Harappan sites, whereas the Iranian copper is rich in Arsenic.[2][12][14]

- Ores of copper as pyrites was identified far before any other civilization.

- Oldest reference of use of indigenous copper metullurgy is found in Indian civilization

- Gold coating of copper ornaments was very popular

रसः वैकृन्तक वा ॥ Mercury

Arthashastra defines the mercury ore thus

काक-अण्ड-भुज-पत्त्र-वर्णो वा वैकृन्तक-धातुः ।। ०२.१२.१६ ।। (Arth. Shast. 2.12.16)[11]

Those ores which are of the colour of the leaf of kánda (Artemisia Indica) or of the leaf of birch are the ores of vaikrintaka.[13]

Mercury is a metal that has been of great alchemical importance in ancient times. Ayurvedic texts have presented the science of using mercury, as Rasashastra.

Extraction Process

Mercury Ores: Cinnabar (Hingula)

It is a volatile metal, which is easily produced by heating cinnabar followed by the downward distillation of mercury vapour. Some of the earliest literary references to the use of mercury distillation come from Indian treatises such as the Arthashastra of Kautilya.

- Sindhur or Vermilion was Cinnabar, mercuric sulphide, was used to make the red/maroon mark on the forehead as described by Charaka.

अयस् ॥ Iron (Ferrum - Fe)

Arthashastra describes the qualities of the Iron ore thus

खरुम्बः पाण्डु-रोहितः सिन्दु-वार-पुष्प-वर्णो वा तीक्ष्ण-धातुः ।। ०२.१२.१५ ।।(Arth. Shast. 2.12.14)[11]

Those ores which are of orange colour (kurumba), or pale-red (pándurohita), or of the colour of the flower of sinduvára (Vitex Trifolia) are the ores of tikshna.[13]

Significant finding of archaeologists is that iron objects were totally absent in the Harappan and Mohenjadaro excavations.[14] However, earliest Iron Age sites in India show that the discovery and use of iron started around 1200 BC indigenously and independently in at least three nuclear zones- Karnataka area in the south, U.P and Rajasthan area in the north and West Bengal-Bihar area in the north-east. The evidences of early experimentation justify the theory of indigenous origin. Since iron could not be melted and cast easily, carburization of thin sheets of iron in charcoal fire and subsequent lamination and forge-welding of alternate layers of uncarburized and carburized sheets proved to be a.spectacular and.useful Indian discovery made much before the era of laminated Egyptian knife dated 900-800 BC.[2]

Iron supplemented copper in the preparation of various tools for hunting and agriculture, apart from household objects and building materials. A survey of ancient literature has provided ample evidence that iron and steel making technology and their difference has been known in the Vedic period (based on references in Rgveda and Yajurvedd) and may be even earlier.[14]

Extraction Process

- Ores of Iron : Haematite (Fe2O3), Magnetite (Fe3O4), Pyrite (FeS)

- Smelting of Iron by ancient reduction processes

- Satvapaatana: Extraction of iron from Biotite by Ayurvedic method called Satvapaatana.

- Carburization and Steel Production (iron carbon alloying) by two processes

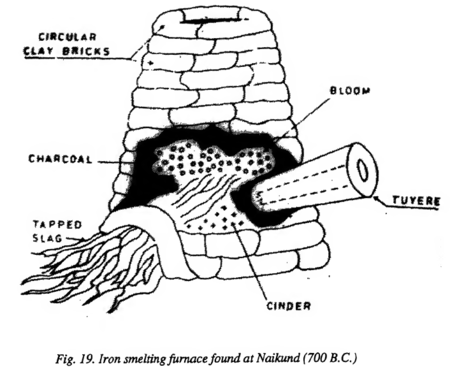

In Bihar, Orissa, and Eastern part of Karnataka the iron smelting was carried out by community called "Asura" and in Central India by the "Aagaria" tribes. While Aagarias smelted the iron ore to produce wrought iron blooms "Lohars" shaped the rough iron to manufacture various tools and objects. Other tribes in India such as Mundias were also involved in smelting of Iron. A number of furnaces have been found at Nalanda, Naikund, Khairadih, Ujjain and many sites in India. Development of reusable furnaces was seen over time.

Ancient Smelting Method

Tradition describes the ancient iron making process which was considered a sacred ritual and the secret of smelting process was highly guarded, transmitted only to the younger generation from the family or tribe. Women also had an active role to play and were designated to do specific jobs in the process. The operation was carried out near ore deposit or in the nearby forest to procure the required wood. The whole operation of the furnace can be divided into five parts[14]

- Collection and preparation of the raw-material : Experienced elders located the suitable deposit of the ore after the due rituals and pujas are performed. Women helped in breaking and transporting the ore. Charcoal was prepared from wood like Irool (Xylia dolaberiformis) Teak, Babul (Acacia arbica), Sal (Shorearubusta), Bamboo (Caleotropis gigantica) etc. yielding dense and heavy charcoal. They also maintained the outside of the furnace and stored sufficient quantity of water.

- Making of the furnace and its dressing : These furnaces were called Bhatti, Kothi or Kosthi and made from locally available clay, and at many places internally lined with natural china clay or a refractory mixture generally used for crucible manufacture. Different kinds of furnaces were made either below the ground level, or on the sloping face of a hillock or above ground level. All furnaces had two holes - one for introducing the blast and other for removing the molten slag. The construction of the furnaces involved many design principles ranging from the clay used, the drying and repatching of the walls, the mathematical aspects such a height, width or slants of the furnace, the specific sizes of the openings at the bottom, the location of the bellows and peep holes to monitor temperature.

- Making of air bellows and their fitting : Air to the furnace is provided by a pair of small bellows made of goat or buffalo skin and connected to the furnace through the bamboo and clay pipes operated by a single person. In later times the size of the bellow was increased but it was maintained so as ancients realized that blowing excess air leads to production of brittle cast iron and not solid sponge or wrought iron.

- Ignition of the furnace and its operation : Once the furnace was ignited after the required preparation with charcoal, bellows were operated to raise the temperature at slow pace. When the furnace was red hot and CO gas was seen burning at the top, the furnace was charged with pre-heated ore and charcoal in alternate layers. The preheating of the ore was done by storing it on the inclined platform. As the maximum temperature was achieved at the tuyere level, by increased air blowing, a small hole was made in the front wall to tap out the molten Fayalite slag. The reduced sponge iron gets consolidated in the hearth by partial fusion, the block of which is removed by breaking the front wall of the furnace.

- Handling of the sponge iron. The hot iron bloom taken out of the furnace is hammered on stone anvil to squeeze out liquid slag before it gets solidified. It is subjected to further heating and refining process.

Ayuvedic Method

In Rasa Ratna Samuccaya and other Ayurvedic text a number of processes have been mentioned for the extraction of iron from Biotite and other iron bearing minerals for the preparation of medicine. This process is known as Satvapaatana, and generally consists of three major steps : (i) Shodhana (purification), (ii) Bhaavana (Maceration and Trituration) (iii) Dhamana (Heating and smelting).[14]

Carburization and Steel Production

The Indian craftsmen had realised the effect of addition of ‘C’ (Carbon) to iron and the excellence of the cutting edges formed on such steel weapons. Wootz steel was being produced in several places in India and exported to the West even as early as 700 B.C. for the manufacture of famous ‘Damascus Swords'. This sword had attained its reputation for edge sharpness, flexibility, strength and the typical surface structure on the sword’s surface.

The carburization of hot sponge or bloom could be done by the following techniques:[14]

- Increasing the carbon content of the hot sponge inside the smelting furnace by raising the furnace temperature and the retention time of the hot sponge for a slightly longer period.

- By increasing the temperature and the time of contact between the hot iron bar and charcoal during secondary refining.

- By selective carburization of cutting edge of the implements by the application of carburizing paste and reheating to 950 to l0000C.

The following two distinct processes have been reported for production of steel from iron.

- By carburization of wrought iron rods and melting in small crucibles.

- By decarburization of white cast iron.

Rasaratnasamucchaya (70-71 shlokas) has given the following classification of iron-carbon alloys. Based on the characteristic features of the fractured surfaces and other properties such as ductility, magnetism and hardness etc, these have been further classified into sub-groups. This type of classification has no parallel in the world.

- Kaanta Loha (soft iron)

- Tikshna Loha (high carbon steel)

- Munda Loha (cast iron)

Important Landmarks

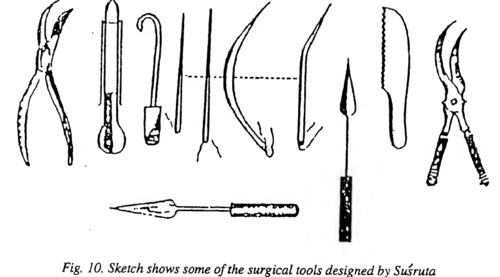

Surgical tools : The Susruta Samhita has mentioned the method of fabrication of more than 100 surgical tools made of Fe-C alloys and the process of heat treatment to obtain razor sharp edge capable of splitting hair into two halves longitudinally.

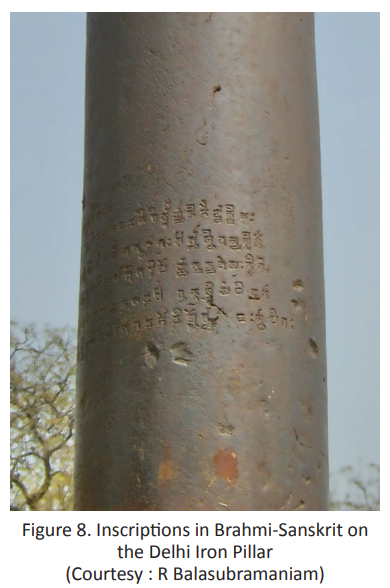

Iron Pillar of Delhi : The forging of wrought iron seems to have reached its zenith in India in the first millennium AD. The earliest large forging is the famous iron pillar with a height of over 7 m and weight of about 6 tons at New Delhi ascribed to Chandragupta Vikramaditya 400- 450 CE . The inscription of the Gupta period of the 4th century CE is in Brahmi script of Sanskrit (Figure 8).The pillar is believed to have been made by forging together a series of disc-shaped iron blooms. The Iron Pillar, the earliest and the largest surviving iron forging in the world, is regarded as a metallurgical marvel because it has defied the laws of corrosion of iron even after so many centuries, earning the nickname, the ‘rustless wonder’. Its astounding corrosion-resistance is partly due to its composition; high slag and phosphorus (0.25 p.c.) content and low manganese (0.05) and sulphur (0.005) content.[2][12]

Wootz Steel : This iron-carbon alloy of repute is the high carbon steel manufactured in the recent past by the crucible process. It is called Wootz Steel, the anglicized version of "ukku" in the languages of the states of Karnataka, and Andhra Pradesh, a term denoting steel. Literary accounts suggest that steel from the southern part of the Indian subcontinent was exported to Europe, China, the Arab world and the Middle East. Studies on Wootz indicate that it was an ultra-high carbon steel with between 1-2% carbon.

- Largest and riches deposits of Hematite and Magnetite all over India

- The Largest and Earliest Rustless Iron Forging Wonder : Iron Pillar of Chandragupta Vikramaditya at Delhi

- Wootz Steel prepared by indigenous crucible process.

- Monumental Iron pillar at Dhar in Central India, and Kodachadri in coastal Karnataka and Iron beams of the Konark temple.

यशद ॥ Zinc (Zinc - Zn)

Arthashastra does not specifically mention about Zinc ores. Zinc is silvery white in colour and very hard and brittle owing to its close packed hexagonal crystal structure. The earliest firm evidence for the production of metallic zinc comes from India. Of the eight metals used in antiquity zinc is one of the most difficult to smelt since it volatalizes at about the same temperature of around 1000°C that is needed to smelt zinc ore. As a result, it forms as a vapour in the furnace which would immediately get reoxidised and hence the pure form is lost. So there are very few references to metallic zinc in early treatises.

In view of the Indian quest for substitute gold, the name for zinc was changed from rasaka (that which is distilled like rasa or mercury) to yashada (that which gives yasha or fame alluding to gold). It is this later Sanskrit word Yashada which was converted to dasta in the other Indian languages and 'zinc' in the European languages.[2]

Extraction Process

- Zinc Ores : Calamine (ZnCO3) and Sphalerite (ZnS)

- Downward draft reduction - distillation process

In India there is unique evidence for the extensive and semi-industrial production of zinc at the Zawar area of Rajasthan. An ingenious method was devised of downward distillation of the zinc vapour formed after smelting zinc ore using specifically designed retorts with condensers and furnaces. The zinc vapour could be cooled down drastically to get a melt that could solidify to zinc metal. The Rasaratnakara, Nagarjuna describes this method of production of zinc.

- Zawar Zinc mines using downward distillation process to produce metallic zinc.

त्रपु ॥ Tin (Stannum - Sn)

Arthashastra describes the qualities of the Tin ore thus

ऊषर-कर्बुरः पक्व-लोष्ठ-वर्णो वा त्रपु-धातुः ।। ०२.१२.१४ ।। (Arth. Shast. 2.12.14)[11]

Those ores which are as variegated in colour as saline soil or which have the colour of a burnt lump of earth are the ores of tin.[13]

Mention of Tin(Trapu,Vanga) has been made in Vedas (Yajurveda 30.14) but no extraction process or specific use has been described till the introduction of bronze. In India very meagre deposits of tin bearing ore have been reported from Hazaribagh and Chota Nagpur area and most probably this metal or its oxide mineral Cassiterite was brought from Burma or Malaya.

लोहाध्यक्षः ॥ Lohadhyaksha

Arthashastra further describes the duties of the Lohadhyaksha who is the appointed person to carry on the activities related to metals.

लोह-अध्यक्षस्ताम्र-सीस-त्रपु-वैकृन्तकारकूट-वृत्त-कंस-ताल-लोह-कर्म-न्तान्कारयेत् । लोह-भाण्ड-व्यवहारं च ।। ०२.१२.२३ ।। (Arth. Shast. 2.12.23)[11]

The superintendent of metals (lóhádhyakshah) shall carry on the manufacture of copper, lead, tin, vaikrintaka (mercury [?]), árakúta (brass), vritta(?); kamsa (bronze or bell-metal), tála (sulphurate of arsenic), and lodhra (?), and also of commodities (bhánda) from them.[13]

Alloys of Metals

The concepts of alloy or mixed metal (mishra loha or yukta) and heat-treatment by quenching (gastrapana) were elaborated in Rasaratnasamucchaya. Alloys of five metals (panchalohas) and eight metals (ashtadhatu) were developed mostly for making auspicious images.

Kamsya Bronze (Tin and Copper)

The earlier bronze was most probably made by co-reduction of mixed ore of Casseterite and Cuprite or oxidized Chalcopyrite.

Arakuta Brass (Zinc and Copper)

Taxila provides the evidences for the brass and zinc artifacts in India. Indian craftsmen continued to make brass through the cementation route, namely reduction of copper ore and zinc ore in the same furnace simultaneously. While zinc oxide is easily reducible at the usual temperature of the smelting furnace, the metal zinc is produced in the vapour state, since it has a low boiling point 917°C. Zinc vapour gets absorbed in copper to produce cementation brass.

The Sanskrit term for gold-like yellow brass was Pita-tala (yellow alloy) or pitala.[2]

References

- ↑ 1.0 1.1 Singh. R. D, (1997) History of Technology in India, Vol. 1, From Antiquity to c. 1200 A.D. by A. K. Bag. New Delhi: Indian National Science Academy. (Chapter Mining: Page 48 - )

- ↑ 2.0 2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 2.9 Minerals and Their Exploitation in Ancient and Pre-modern India by Prof. A. K. Biswas

- ↑ Atharvaveda (Kanda 4 Sukta 10)

- ↑ Atharvaveda Subodh Bhashya, Volume 1 (Pages 163-164)

- ↑ Chandogya Upanishad (Adhyaya 4 Khanda 17)

- ↑ Mm. Ganganath Jha. (1923) Chhandogya Upanishad and Sri Sankara's Commentary. Madras: The India Printing Press. (Page 261)

- ↑ Arthashastra by Kautilya (Adhikarana 2 Adhyaya 17)

- ↑ Chattopadhyaya, Debiprasad. (1991) History of Science and Technology in Ancient India ll Formation of the Theoretical Fundamentals of Natural Science. Calcutta: Firma KLM Pvt. Ltd.,

- ↑ 9.0 9.1 Sastri, V. Subrahmanya and Bhat. M. Ramakrishna, (1946) Varahamihira's Brihat Samhita with an English Translation and Notes. Bangalore City: V. B. Soobbiah and Sons (Page 628 - 629)

- ↑ 10.0 10.1 10.2 10.3 Biswas, Arun Kumar. (1997) History of Technology in India, Vol. 1, From Antiquity to c. 1200 A.D. by A. K. Bag. New Delhi: Indian National Science Academy. (Chapter Mining: Page 225 - 255)

- ↑ 11.0 11.1 11.2 11.3 11.4 11.5 11.6 11.7 11.8 Arthashastra by Kautilya (Adhikarana 2 Adhyaya 12)

- ↑ 12.0 12.1 12.2 12.3 Srinivasan, Sharada and Ranganathan, Srinivasa. (2013) Minerals and Metals Heritage of India. Bangalore:National Institute of Advanced Studies.

- ↑ 13.0 13.1 13.2 13.3 13.4 13.5 13.6 13.7 Shamasastry. R. Kautilya's Arthashastra with English Translation. (Pages 111 - 115)

- ↑ 14.0 14.1 14.2 14.3 14.4 14.5 14.6 14.7 14.8 14.9 Bhanu Prakash (1997) History of Technology in India, Vol. 1, From Antiquity to c. 1200 A.D. by A. K. Bag. New Delhi: Indian National Science Academy. (Chapter Metals and Metallugy: Page 80 )